Product Description

Quick Details

| Shape: | Pinion | Place of Origin: | HangZhou, China | Model Number: | qqq0 |

| Brand Name: | AT |

Packaging & Delivery

| Packaging Details: | Neutral Packing or Customized Packing |

| Delivery Detail: | 25-30 days after the order confirmed |

Product Description

| Product | Rack and pinion plastic Steel gear rack motor Automatic gate gear rack Sliding door gear rack manufacturer |

| Application | Machine tools |

| Specifications / Features | Precision production machine Strictly quality control system Teeth and bevel spiral gear specifications are available OEM/ ODM orders welcome |

| Primary competitive advantages | Customized Quality Approvals Country of Origin Green Product Reputation After-sales service Product Performance Small Orders Accepted Experienced Staff Prompt Delivery |

| Main Export Markets | Asia Australasia Central / South America Eastern Europe Mid East / Africa North America Western Europe |

ABOUT US:

As your one-stop source, AT PRECAST,we design, manufacturer and distribute precast concrete accessories including the Lifting Systems and Anchoring systems Coil and Ferrule Inserts. for Concrete and Prefabricated area.

As a leader in developing concrete accessory products, our main goal is to produce products that are safer, faster and more cost efficient.

With more than totally 50 years working experience, our entire staff is dedicated to provide you with the best customer service and competitive prices. Our sales force are able to answer your questions quickly and offer you technical support .

Assurance:

100% quality manufacturing.

We guarantee that our products meet your supplied specifications

Extremely competitive pricing

Delivery to your port or front door

4 —- 8 week lead times

We handle all paperwork

Partial container orders

Flexible payment options

Unique tooling options

Full range of packaging options from bulk to retail ready

Complete testing services available

FAQs:

1. Where is your location?

We are located in HangZhou City of China and are closed to Airport. It takes 30minuts by car from Liuting Airport our company.

2. How long has the company been established?

AT INDUSTRY was established in 2009. There is 6 years exporting experiences.

3. How many employees do you have?

Administration / sales 4

Engineering / design as our partner 8

Production as our partners 120

Quality assurance / inspection 10

4. Which countries do you export to?

U.S.A, Germany, France, Italy, UK, Brazil, Middle east of Asia, Thailand,

5. What proportion of your goods are exported?

100% of our production are exported to all over the world.

6. How long does it take to receive samples?

a) Pattern:30-45days after order

b) Sample:30days after pattern finishing.

c) The lead time is the general production period and does not include the transportation time.

7. New product development process

Got tooling order and sample order with 50% deposit—Hold a meeting with the relation dept. to ensure the developing schedule—Design pattern, fixture and gauge and making them in our house—mold steel buying—Machining—Inspection—Send out the sample with initial inspection report.

8. How long is the manufacturing lead time?

Mass Production: 90days after sample approval by yours.

The lead time is the general production period including the transportation time.

We could make some special production arrangement effectively if customer has urgent need.

9. What basis can we buy goods?

We generally offer customers prices FOB& CIF (Carriage, Insurance & Freight). The CIF includes the freight cost to your nominated sea port.

We do provide clearance of goods which needs to be handled by a local freight forwarder.

All local costs and taxes are the responsibility of the buyer. We are happy to offer advisement on shipping if required.

10. What are the payment terms?

Payment terms are negotiable and will improve for long term customers.

During the initial stages, we request 50% of tooling fee in advance with the balance payable on acceptance of samples.

Production orders can be negotiable. We prefer 50% deposit and the balance by T/T before sails. But sometimes T/T 30 days after sails would also acceptable.

11. Which currency can we buy in?

We can deal in USD / Euro currency / GBP.

12. How long does it take to ship goods from China by sea?

It takes about 5 weeks to European ports plus 1 week customs clearance, so you can get the container within 6 to 7 weeks. It takes about 2 weeks to east coast and 3 weeks to west coast US ports. All sea goods are shipped from HangZhou Port.

13. How long does it take to ship goods from China by air?

It takes about 7 days to all major destinations.

14. Can we visit the factory to conduct an audit?

Yes, you are welcome to visit our partner factory by prior agreement.

15. How do we retain client confidentiality?

We are happy to CHINAMFG Confidentiality Agreements with customers and will honor them.

16. Which languages do we do business in?

Although we do business with many countries around the world, we can only communicate effectively in Chinese English.

All information supplied should therefore be supplied in this form.

17. Is there a minimum volume of business required to conduct international purchasing?

There are no minimum volumes, but the prices of the goods, plus the fixed costs of importing makes it more economical to buy in high volumes. All potential customers will be assessed on an individual basis to determine if it appears a viable option for all parties to develop a relationship.

18. What type of parts you are specialized in?

Our business contains 2 areas,

one is for construction precast including lifting system, rigging hardware metal parts.

Another is customized metal business of quality sand castings, investment castings, lost foam castings, hot forgings, cold forgings, stampings, machined parts, injectionmolded plastics parts, etc.

19. Which kind of equipments do you have?

Forging friction press 160Ton, 300Ton, 630Ton, 1200Ton

Casting CHINAMFG of 200kg, 500kg,1000kgs, 2000kgs

Press of 63ton, 120tons

CNC Machining center

CNC Vertical Lathe

CNC Lathe center

Boring machine

Drilling machine

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Machine |

|---|---|

| Hardness: | Hardened |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Type: | Worm And Wormwheel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

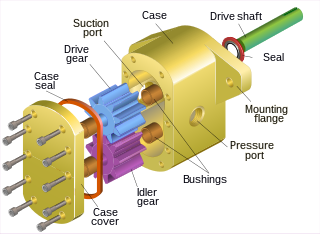

Can gear pumps be used in chemical processing and manufacturing?

Yes, gear pumps can be effectively used in chemical processing and manufacturing. Here’s a detailed explanation:

1. Chemical Compatibility:

Gear pumps are available in a variety of materials, including stainless steel, cast iron, and non-metallic options such as PTFE or PVC. This wide range of material options allows gear pumps to handle a diverse range of chemicals, acids, solvents, and corrosive fluids commonly used in chemical processing and manufacturing. Proper material selection ensures compatibility and prevents chemical reactions or contamination.

2. Precise Flow Control:

Gear pumps offer precise flow control, making them suitable for applications where accurate dosing or metering of chemicals is required. The positive displacement operation of gear pumps ensures consistent and repeatable flow rates, allowing precise control over the amount of fluid being transferred. This feature is critical in chemical processing and manufacturing, where precise quantities of chemicals need to be mixed or added to achieve desired formulations or processes.

3. Viscosity Handling:

Chemical fluids can vary widely in viscosity, ranging from thin solvents to highly viscous liquids. Gear pumps are capable of handling fluids with different viscosities due to their positive displacement action. They can effectively transfer low-viscosity fluids as well as thicker or more viscous substances, ensuring reliable fluid transfer in chemical processing and manufacturing applications.

4. Reliability and Durability:

Chemical processing and manufacturing often involve demanding operating conditions, including high pressures and corrosive environments. Gear pumps are known for their reliability and durability in such challenging conditions. They are designed to withstand high pressures and can be constructed using corrosion-resistant materials, ensuring long-term performance and minimizing downtime in chemical processing and manufacturing operations.

5. Versatility:

Gear pumps are versatile and can handle a wide range of chemical applications. They can be used for transferring chemicals between containers, pumping chemicals into reactors or mixers, circulating fluids in chemical processes, and more. Their adaptability to different chemical processing and manufacturing tasks makes gear pumps a valuable asset in these industries.

6. Ease of Maintenance:

Gear pumps have a relatively simple design with few moving parts, making them easy to maintain. Routine maintenance tasks such as lubrication, seal replacement, or inspection can be performed with ease, minimizing downtime and ensuring continuous operation in chemical processing and manufacturing facilities.

In summary, gear pumps are well-suited for chemical processing and manufacturing applications due to their chemical compatibility, precise flow control, viscosity handling capabilities, reliability, versatility, and ease of maintenance. These features make gear pumps a dependable choice for transferring a wide range of chemicals and ensuring efficient and consistent processes in these industries.

Can gear pumps handle abrasive and corrosive fluids effectively?

Gear pumps are generally not the most suitable choice for handling abrasive and corrosive fluids effectively. Here’s a detailed explanation:

1. Abrasive Fluids:

Abrasive fluids contain solid particles that can cause wear and damage to pump components. Gear pumps have tight clearances between the gear teeth and the pump housing, and the presence of abrasive particles can lead to accelerated wear and reduced pump efficiency. The abrasive particles can cause erosion of the gears, housing, and other internal surfaces, leading to increased clearances and decreased pump performance over time. While gear pumps may be able to handle some mildly abrasive fluids, they are not designed for heavy-duty abrasive applications.

2. Corrosive Fluids:

Corrosive fluids can chemically attack and degrade the materials used in gear pumps. Many gear pumps are constructed using materials such as cast iron, stainless steel, or bronze, which offer good resistance to corrosion in a wide range of fluids. However, highly corrosive fluids, such as strong acids or alkalis, can still cause damage to these materials over time, leading to leaks, reduced performance, or even pump failure. In corrosive fluid applications, it is often necessary to use specialized materials or corrosion-resistant coatings to protect the pump components.

3. Alternative Options:

For handling abrasive and corrosive fluids effectively, alternative pump technologies are often preferred. Some options include:

- Diaphragm Pumps: Diaphragm pumps use a flexible diaphragm to handle abrasive and corrosive fluids. The diaphragm separates the fluid from the pump components, protecting them from direct contact with the fluid.

- Peristaltic Pumps: Peristaltic pumps use a flexible tube or hose to transport fluids. The fluid only comes into contact with the tube, which can be made from materials resistant to abrasion and corrosion.

- Centrifugal Pumps: Centrifugal pumps are often used for abrasive and corrosive fluids. They rely on the centrifugal force generated by a rotating impeller to move the fluid, and they can be constructed with materials that withstand the corrosive effects of the fluid.

- Progressive Cavity Pumps: Progressive cavity pumps use a rotating screw-like rotor inside a rubber stator to transfer fluids. The design allows for gentle handling of abrasive and corrosive fluids without significant wear or damage.

In summary, while gear pumps can handle some mildly abrasive fluids and certain corrosive fluids, they are not typically the most effective choice for handling highly abrasive or corrosive fluids. For such applications, alternative pump technologies that are specifically designed to handle abrasive or corrosive fluids should be considered to ensure optimal performance, longevity, and reliability.

How does a gear pump contribute to pumping viscous fluids?

A gear pump is particularly effective in pumping viscous fluids due to several contributing factors. Here’s a detailed explanation:

1. Positive Displacement:

One of the key advantages of gear pumps is their positive displacement operation. As the gears rotate, they create expanding and contracting chambers between the gear teeth and the pump casing. This positive displacement action effectively traps and carries a fixed volume of fluid with each revolution, regardless of its viscosity.

2. Close Tolerance Design:

Gear pumps are designed with close tolerances between the gears and between the gears and the casing. This tight clearance helps to minimize internal leakage and slippage of the fluid, ensuring efficient transfer of even highly viscous fluids. The close tolerance design also contributes to the pump’s ability to generate high pressures, which may be required when pumping viscous fluids.

3. Gear Tooth Geometry:

The gear tooth geometry of a gear pump plays a significant role in pumping viscous fluids. Gear pumps typically use gears with large tooth clearances and relatively large tooth depths. This design allows for better fluid flow and reduces the likelihood of fluid entrapment between the gear teeth. The gear tooth geometry promotes smoother and more effective displacement of viscous fluids.

4. Slow Speed Operation:

Pumping viscous fluids often requires slower pump speeds to maintain efficient flow. Gear pumps are well-suited for this purpose as they can operate at lower speeds without sacrificing their positive displacement characteristics. The slower speed allows the fluid more time to fill the expanding chambers between the gear teeth, resulting in improved pumping efficiency.

5. Heating and Insulation:

In some cases, heating the viscous fluid or insulating the pump can contribute to better fluid transfer. Gear pumps can be designed with heating or jacketing options to provide controlled heating of the fluid, reducing its viscosity and facilitating easier pumping. Insulation can also help maintain the fluid’s temperature during the pumping process, preventing excessive cooling and thickening of the fluid.

6. Material Selection:

Gear pumps can be constructed using materials that are well-suited for handling viscous fluids. Materials such as cast iron, stainless steel, or specific polymers may be chosen based on the compatibility with the viscous fluid’s characteristics. Proper material selection ensures the pump’s longevity and minimizes the risk of damage or clogging when pumping viscous fluids.

Overall, the positive displacement operation, close tolerance design, gear tooth geometry, slow speed operation, heating and insulation options, and material selection of gear pumps collectively contribute to their effectiveness in pumping viscous fluids. These factors enable gear pumps to handle a wide range of viscosities and ensure efficient fluid transfer in various industrial applications.

editor by CX 2023-09-28